The Ultimate Guide to Understanding Screw Air Compressors and Their Benefits

The screw air compressor has emerged as a vital component in various industrial applications, providing an efficient and reliable source of compressed air. According to a recent report by MarketsandMarkets, the global air compressor market is projected to reach $41.8 billion by 2027, with screw air compressors playing a significant role due to their ability to deliver high performance and energy savings. These compressors utilize a unique rotary screw mechanism that ensures continuous operation, reducing maintenance costs and downtime. Furthermore, industry studies indicate that screw air compressors can achieve energy efficiency levels up to 15-20% higher than traditional piston compressors, making them an increasingly popular choice among manufacturers. As industries continue to focus on sustainability and cost-effectiveness, understanding the ins and outs of screw air compressors and their distinct benefits becomes essential for optimizing operational efficiency and driving competitive advantage.

Understanding the Basics of Screw Air Compressors: How They Work and Key Components

Screw air compressors are an essential component in various industrial applications, known for their efficiency and reliability. Understanding how they work and their key components can help users appreciate their benefits in comparison to traditional air compressors.

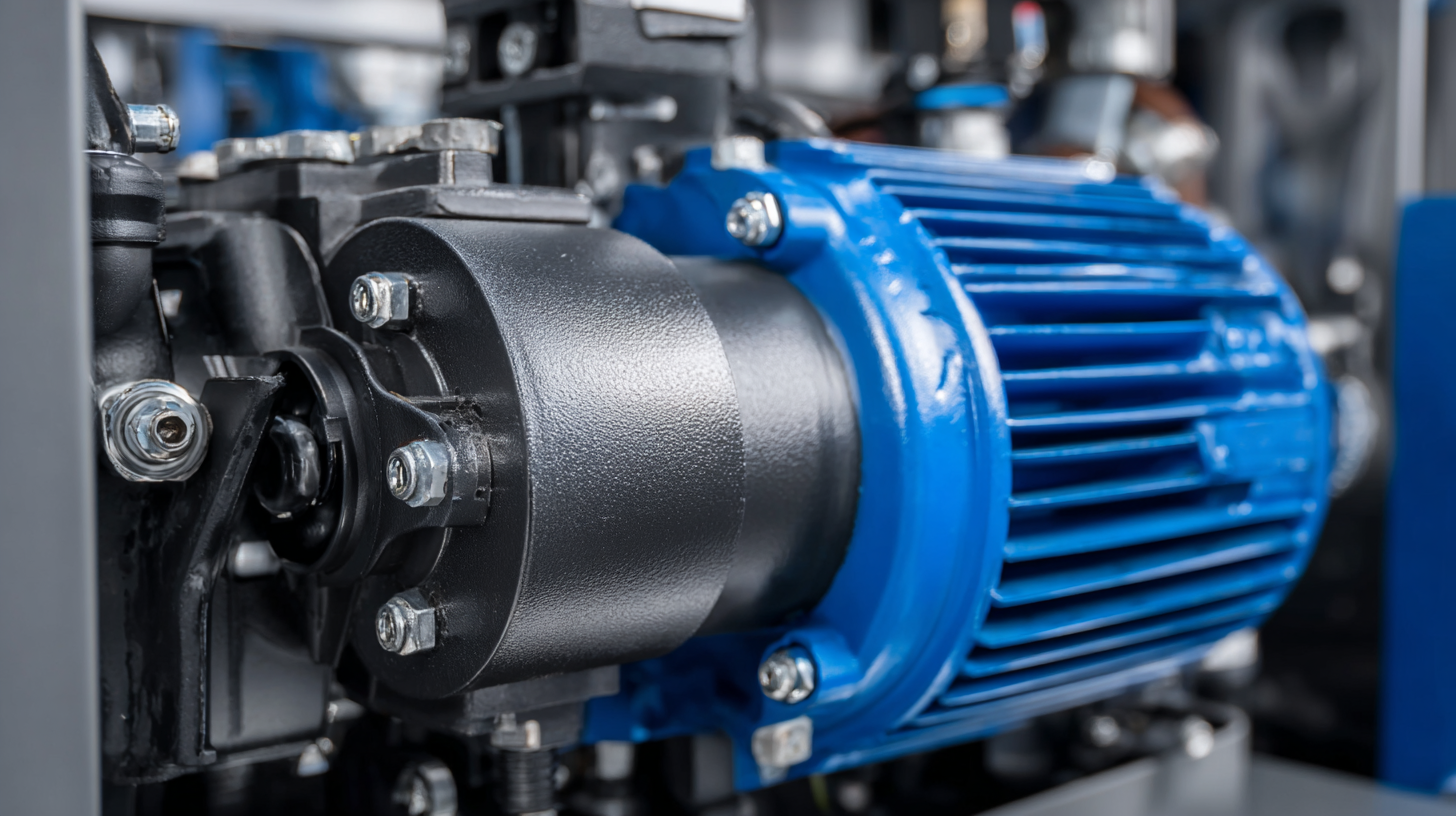

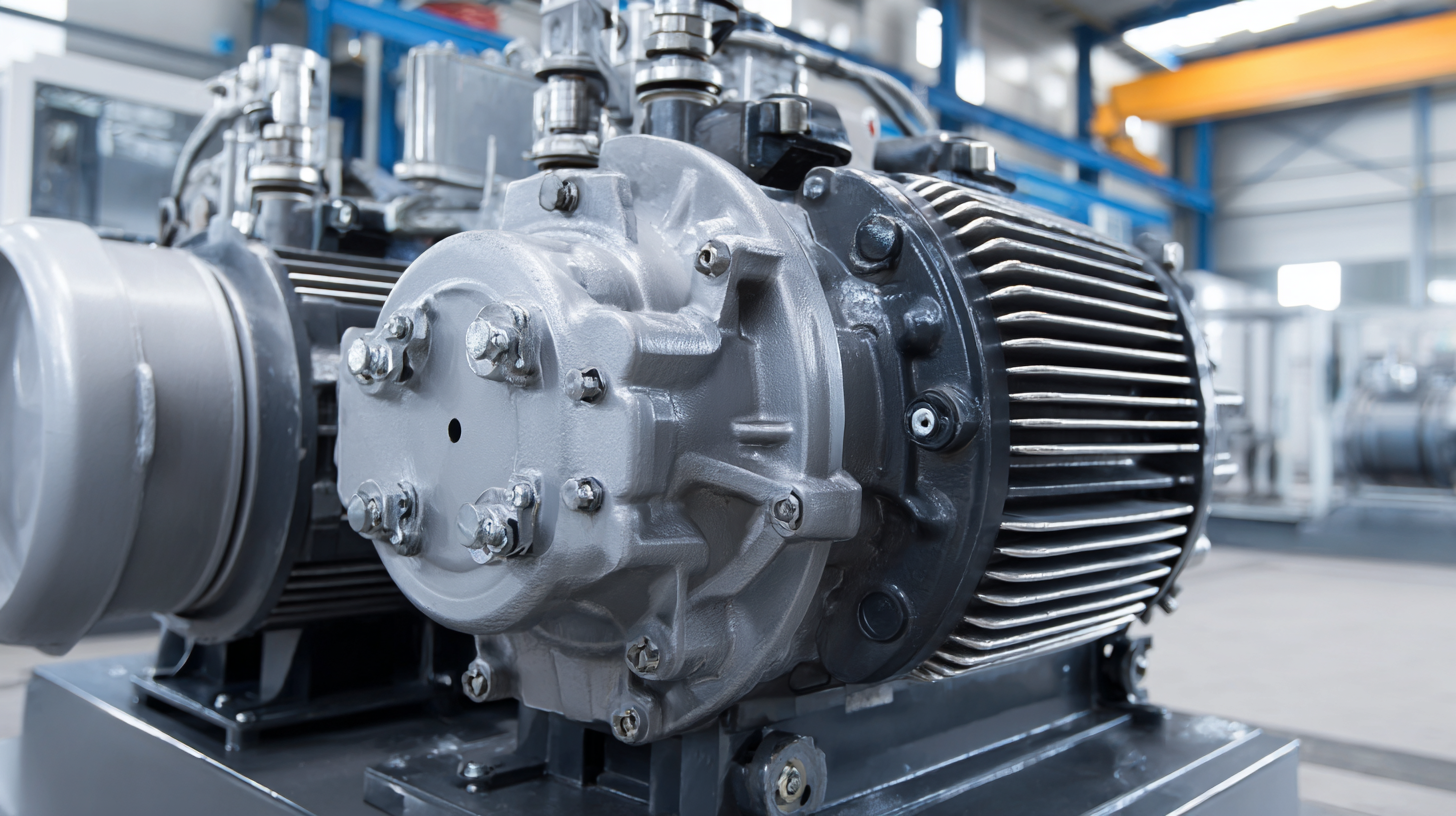

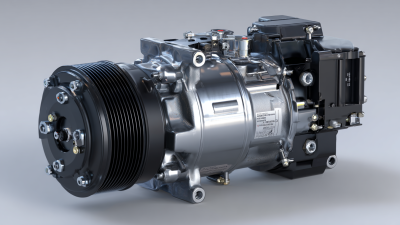

At the core of a screw air compressor is a pair of helical rotors that compress air through a continuous process. As the rotors turn, air enters the compression chamber and is trapped, reducing its volume and raising its pressure before it is discharged.

Screw air compressors are an essential component in various industrial applications, known for their efficiency and reliability. Understanding how they work and their key components can help users appreciate their benefits in comparison to traditional air compressors.

At the core of a screw air compressor is a pair of helical rotors that compress air through a continuous process. As the rotors turn, air enters the compression chamber and is trapped, reducing its volume and raising its pressure before it is discharged.

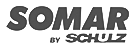

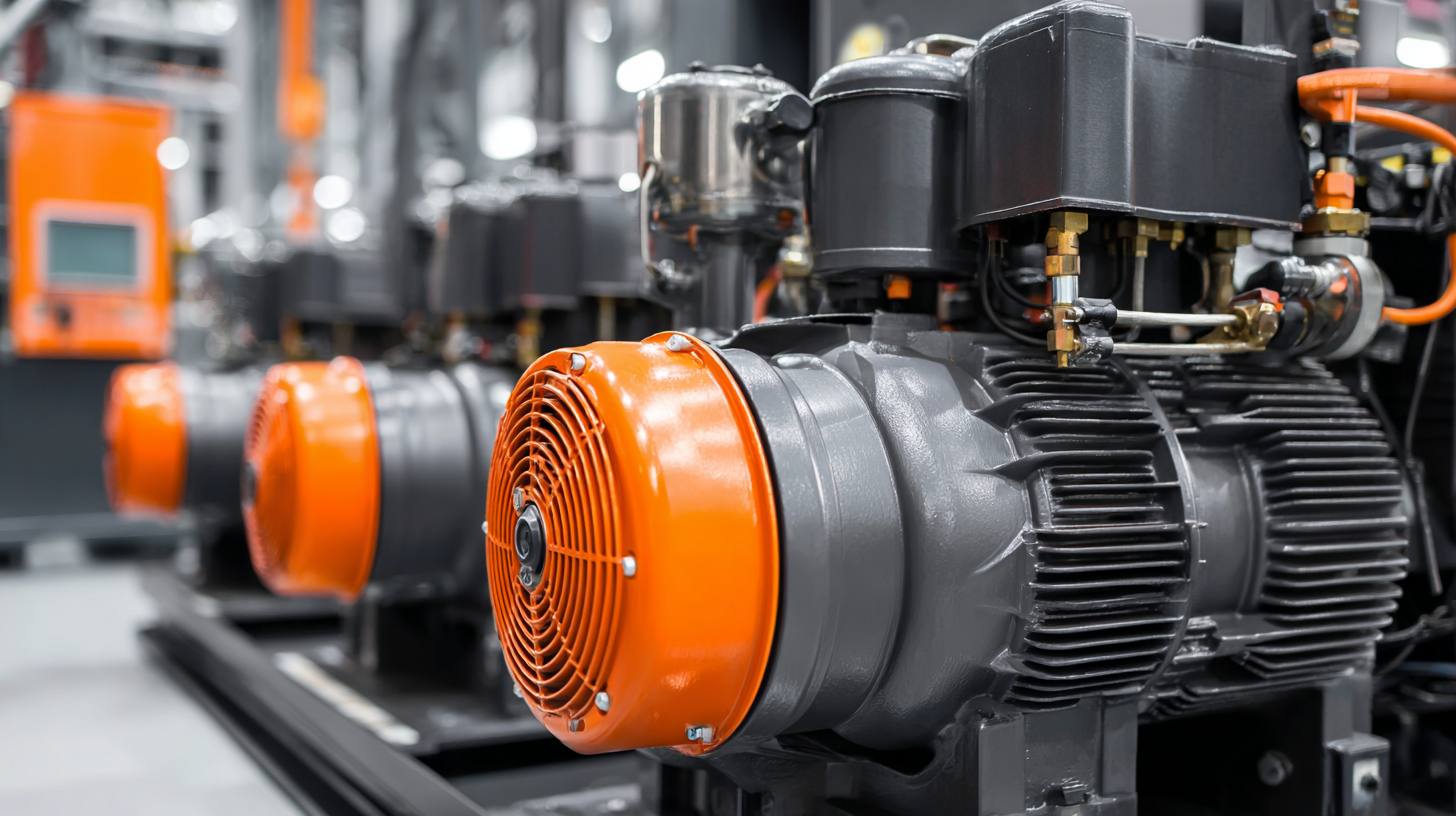

The main components of a screw air compressor include the air end, which houses the rotors; the motor, which drives the rotors; and various cooling and lubricating systems that ensure optimal performance. The design of screw compressors allows for smoother and quieter operation, making them ideal for environments where noise levels are a concern. Additionally, they tend to require less maintenance than other types of compressors, which can lead to cost savings over time.

Understanding these basics helps users optimize their use of screw air compressors, ensuring they gain maximum efficiency and longevity from their equipment.

Top 5 Advantages of Using Screw Air Compressors for Your Business Needs

Screw air compressors have become increasingly popular in various industries due to their numerous advantages. One of the primary benefits is their efficiency. Unlike traditional piston compressors, screw compressors operate continuously, which helps reduce energy consumption and eliminate energy losses associated with pulsating airflow. This makes them an ideal choice for businesses seeking sustainable and cost-effective solutions.

Another significant advantage is their durability and low maintenance needs. Screw compressors are designed with fewer moving parts, resulting in less wear and tear over time. This reliability translates into longer service intervals and reduced downtime for businesses, allowing for smoother operations. Additionally, their compact design often requires less space, making them suitable for various work environments. The overall reliability and efficiency of screw air compressors position them as a valuable investment for businesses looking to enhance their productivity and reduce operational costs.

Choosing the Best Screw Air Compressor: Factors to Consider Before Purchase

When selecting the best screw air compressor for your needs, several factors come into play. First and foremost, consider the compressor’s capacity and pressure requirements. Different applications require varying airflow and pressure levels; thus, it's crucial to choose a compressor that meets your specific operational demands. Assessing your current and future compressed air needs will help avoid underperformance or overspending on unnecessary capacity.

Another essential factor is the energy efficiency of the screw air compressor. With energy costs being a significant portion of operational expenses, looking for models with high efficiency ratings can lead to substantial long-term savings. Additionally, consider the maintenance requirements and ease of access for servicing, as these will impact downtime and operational efficiency. Evaluate the build quality and the manufacturer's reputation, ensuring you select a durable compressor that can withstand the rigors of continuous operation.

The Ultimate Guide to Understanding Screw Air Compressors and Their Benefits - Choosing the Best Screw Air Compressor: Factors to Consider Before Purchase

| Feature | Description | Importance |

|---|---|---|

| Type of Drive | Direct Drive, V-Belt Drive | Affects efficiency and maintenance requirements |

| Power Rating | Measured in horsepower (HP) or kilowatts (kW) | Determines the compressor's capacity and output |

| Pressure Range | Typical ranges from 5 to 150 psi | Essential for specific applications |

| Oil-Free vs. Oil-Lubricated | Options for clean air applications | Critical for industries like food and pharmaceuticals |

| Cooling System | Air-cooled or water-cooled | Influences performance and space requirements |

| Size and Portability | Stationary or portable models | Affects suitability for different environments |

| Noise Level | Measured in decibels (dB) | Important for work environment and regulations |

| Initial Cost | Upfront purchase price | Budget considerations and total ownership cost |

Maintenance Tips for Prolonging the Lifespan of Your Screw Air Compressor

Proper maintenance of screw air compressors is essential for maximizing their lifespan and ensuring efficient performance. One of the key maintenance tips is to regularly check and replace the air filter. A clean air filter prevents dirt and debris from entering the compressor, which can cause wear and reduce efficiency. It's recommended to inspect the filter monthly and replace it at least twice a year to keep the system running smoothly.

Additionally, monitoring the oil levels and quality is crucial. Screw air compressors rely on oil for lubrication and cooling, and insufficient or contaminated oil can lead to severe damage. Regularly check the oil levels and change the oil according to the manufacturer's recommendations. Implementing a routine schedule for inspecting belts, hoses, and other components will also help identify potential issues before they become significant problems, ultimately extending the operational life of your equipment.

Comparing Screw Air Compressors to Other Types: Why They Stand Out

When it comes to choosing an air compressor, screw compressors often emerge as a superior option compared to their piston or reciprocating counterparts. The design of screw compressors allows for continuous airflow, which results in a higher volume of compressed air and improved efficiency during operation. Unlike piston compressors that work in a stop-and-start manner, screw compressors maintain a steady output, making them ideal for industries requiring consistent air supply, such as manufacturing and automotive sectors.

Moreover, screw air compressors tend to operate more quietly than other types due to their smoother operation and lower vibration levels. This feature not only enhances the work environment but also reduces wear and tear on the machine, leading to longer service life and lower maintenance costs. Additionally, their compact design and energy efficiency provide businesses with the advantage of space-saving installations and reduced energy bills, solidifying their position as a preferred choice over traditional compressor types.

Related Posts

-

Global Excellence in Manufacturing: The Pride of China’s Best Screw Air Compressors

-

Benefits of Choosing the Best Screw Compressors for Your Business Needs

-

Solutions for Sourcing the Best Compressor Parts: Boost Efficiency with Quality Components

-

Advantages of Using Scroll Compressors in Modern Applications

-

Finding Quality Suppliers for Best Air Dryers with Industry Insights and Data

-

5 Best Screw Compressor Parts You Should Invest In