How to Choose the Right Air Compressor Parts for Optimal Performance

Choosing the right air compressor parts is crucial for maintaining optimal performance and efficiency in various industrial applications. According to a recent report by the Air Conditioning, Heating and Refrigeration Institute (AHRI), approximately 30% of energy consumption in industrial settings stems from compressed air systems, highlighting the importance of proper maintenance and part selection.

Furthermore, improper or substandard air compressor parts can lead to a significant increase in operational costs, with some estimates suggesting losses can amount to several thousand dollars annually due to inefficiencies. As the market for air compressor systems continues to grow, projected to reach $40 billion by 2027, making informed choices about air compressor parts becomes essential for businesses seeking reliability and cost-effectiveness.

This guide aims to provide insights into selecting the most suitable air compressor parts that not only enhance performance but also contribute to a more sustainable operational footprint.

Furthermore, improper or substandard air compressor parts can lead to a significant increase in operational costs, with some estimates suggesting losses can amount to several thousand dollars annually due to inefficiencies. As the market for air compressor systems continues to grow, projected to reach $40 billion by 2027, making informed choices about air compressor parts becomes essential for businesses seeking reliability and cost-effectiveness.

This guide aims to provide insights into selecting the most suitable air compressor parts that not only enhance performance but also contribute to a more sustainable operational footprint.

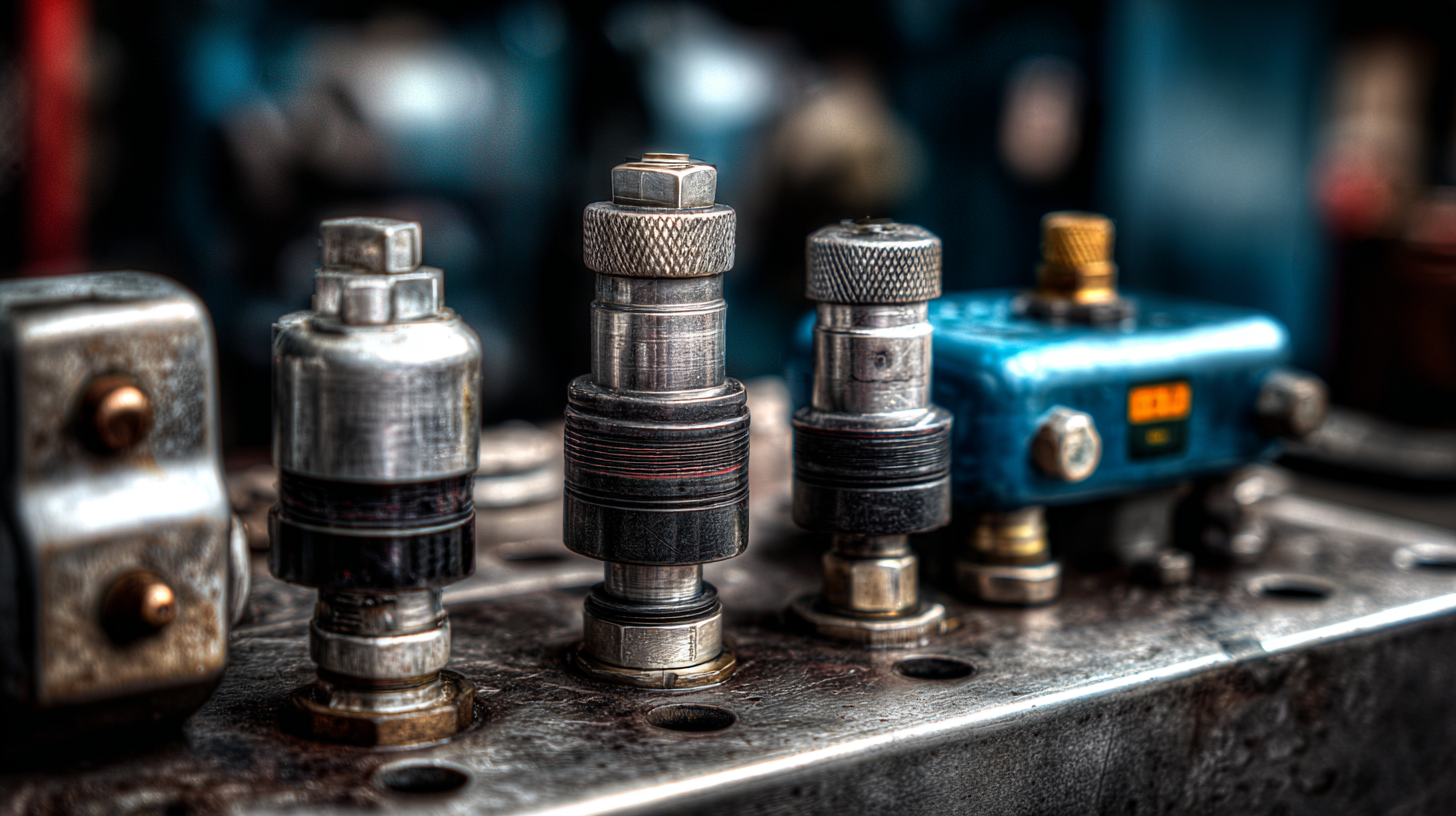

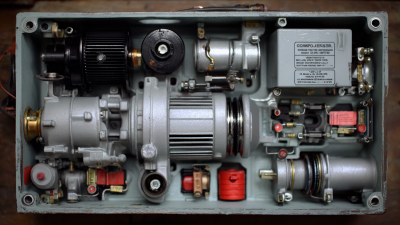

Understanding the Essential Components of Air Compressors for Enhanced Efficiency

Choosing the right air compressor parts is crucial for ensuring optimal performance and enhancing efficiency. Each component, from the motor to the tank, plays a significant role in the compressor's overall functionality. Reports from the Compressors and Pump Industry indicate that proper selection of parts can increase energy efficiency by up to 20%, positively impacting operational costs. Understanding components like the pressure switch, filters, and regulators can help users make informed decisions that lead to better performance.

Tips: When selecting parts, always consider the compatibility with existing equipment. For instance, using a high-efficiency air filter can not only extend the lifespan of the compressor but also ensure cleaner air output, which is vital for sensitive applications. Additionally, investing in quality pressure switches can prevent over-pressurization, safeguarding both the compressor and the operators.

Maintaining an awareness of the required specifications is also important. Industry reports suggest that keeping the air compressor’s pressure settings within optimal ranges can prevent excess wear, decreasing maintenance costs significantly. Regularly checking components and replacing them as needed ensures that the compressor runs smoothly and efficiently, maximizing productivity.

Evaluating the Impact of Compressor Type on Performance and Longevity

When selecting air compressor parts, understanding the type of compressor is crucial for achieving optimal performance and longevity. Different types of compressors, such as reciprocating, rotary screw, and centrifugal, have unique characteristics that influence their efficiency and durability. For instance, reciprocating compressors are known for their robustness and suitability for intermittent use, while rotary screw compressors provide a continuous flow of compressed air with greater efficiency, making them ideal for industrial applications. The design and operating principles of these compressors can significantly affect energy consumption and wear and tear on components.

When selecting air compressor parts, understanding the type of compressor is crucial for achieving optimal performance and longevity. Different types of compressors, such as reciprocating, rotary screw, and centrifugal, have unique characteristics that influence their efficiency and durability. For instance, reciprocating compressors are known for their robustness and suitability for intermittent use, while rotary screw compressors provide a continuous flow of compressed air with greater efficiency, making them ideal for industrial applications. The design and operating principles of these compressors can significantly affect energy consumption and wear and tear on components.

Moreover, the parts chosen for these compressors play a vital role in maximizing their performance. High-quality components such as air filters, oil separators, and pressure switches can enhance performance and extend the service life of the compressor. Considering the specific demands of the application, such as pressure requirements and duty cycles, will help in selecting parts that not only fit well but also contribute to the overall efficiency of the system. Ultimately, aligning the compressor type with the right parts will lead to reduced maintenance costs and improved reliability over time.

Key Considerations for Selecting the Right Air Compressor Motors

Choosing the right motor for your air compressor is crucial for ensuring optimal performance and efficiency. According to a report from the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), approximately

75% of an air compressor's performance is attributed to its motor efficiency. Selecting a motor with the appropriate

horsepower (HP) is fundamental; too little power can lead to underperformance, while excessive HP can result in unnecessary energy consumption.

Additionally, consider the type of motor: permanent split capacitor (PSC) motors are often praised for their reliability and cost-effectiveness, especially in lower HP applications,

while variable frequency drive (VFD) motors allow for adjustable speeds, catering to varying air demands and significantly improving energy efficiency.

The U.S. Department of Energy emphasizes that the adoption of VFD technology can reduce motor energy consumption by as much as

50%, highlighting its importance in modern air compressor systems. Always evaluate the service factor and ensure compatibility with your specific compressor model to maximize longevity and performance.

The Role of Air Filters in Maintaining Optimal Compressor Functionality

Air filters play a crucial role in maintaining the optimal functionality of air compressors. These components prevent dust, dirt, and other contaminants from entering the compressor system, which can lead to wear and tear or even catastrophic failures. A clean air filter ensures that only filtered air is drawn into the compressor, promoting efficiency and longevity. Regular monitoring and replacement of air filters are essential to ensure uninterrupted operation and to maintain performance levels.

**Tips:** When selecting air filters, consider the specific requirements of your compressor and operating environment. Look for filters that have high dirt-holding capacity and are easy to clean or replace. Regularly check the filter for blockages or damage, and adhere to a maintenance schedule to swap out filters before performance degradation occurs. Proper airflow is vital, as a clogged filter can reduce efficiency, increase energy consumption, and cause overheating.

In addition to choosing the right air filter, it’s important to install it correctly. Ensure the filter fits snugly and is positioned in the airflow direction as specified by the manufacturer. Improper installation can lead to leaks, allowing unfiltered air into the compressor system. Following these guidelines can help maintain the health of your air compressor while optimizing its performance and extending its service life.

How to Choose the Right Air Compressor Parts for Optimal Performance - The Role of Air Filters in Maintaining Optimal Compressor Functionality

| Part Type | Material | Efficiency Rating | Replacement Frequency (Months) | Cost ($) |

|---|---|---|---|---|

| Air Filter | Polyester | High | 6 | 20 |

| Oil Filter | Cellulose | Medium | 3 | 15 |

| Regulator | Aluminum | High | 12 | 40 |

| Separator | Synthetic Fiber | Very High | 12 | 60 |

| Belt | Rubber | Medium | 24 | 25 |

Importance of Regular Maintenance and Quality Parts for Compressor Reliability

Regular maintenance of air compressor systems is crucial for ensuring their reliability and optimal performance. Without proper upkeep, even the highest quality components can falter, leading to breakdowns and costly repairs. Scheduled inspections, timely replacements of worn-out parts, and adherence to manufacturer guidelines can significantly extend the lifespan of the compressor. By maintaining a routine maintenance schedule, operators can identify potential issues before they escalate, ensuring that the compressor operates smoothly and efficiently.

In addition to maintenance, selecting quality parts is equally important for the overall functionality of air compressors. Using subpar components can lead to inefficiencies, increased wear and tear, and even catastrophic failures. High-quality parts are designed to withstand the specific demands of compression systems and often come with warranties that provide added security for users. Investing in reliable components not only boosts performance but also enhances the safety and stability of the operations, ultimately resulting in lower operational costs and better output. Prioritizing both maintenance and the use of quality parts is essential for any business relying on air compressors.

Performance Impact of Air Compressor Parts Quality and Maintenance

This chart illustrates the impact of regular maintenance and the use of quality parts on air compressor performance. Regular maintenance and the use of high-quality parts can lead to significant performance improvements, while neglecting maintenance or opting for cheap parts can drastically reduce efficiency.

Related Posts

-

Unleashing the Power of Chinese Manufacturing in Best Air Compressor Spare Parts

-

10 Essential Tips for Choosing the Best Air Compressor Spare Parts

-

7 Essential Tips for Finding the Best Compressor Parts for Your Needs

-

The Ultimate Guide to Selecting the Best Compressor Pumps: Industry Insights and Expert Tips

-

5 Reasons Best Screw Compressor Parts Enhance Your Operational Efficiency

-

7 Best Air Dryers That Transform Your Drying Experience