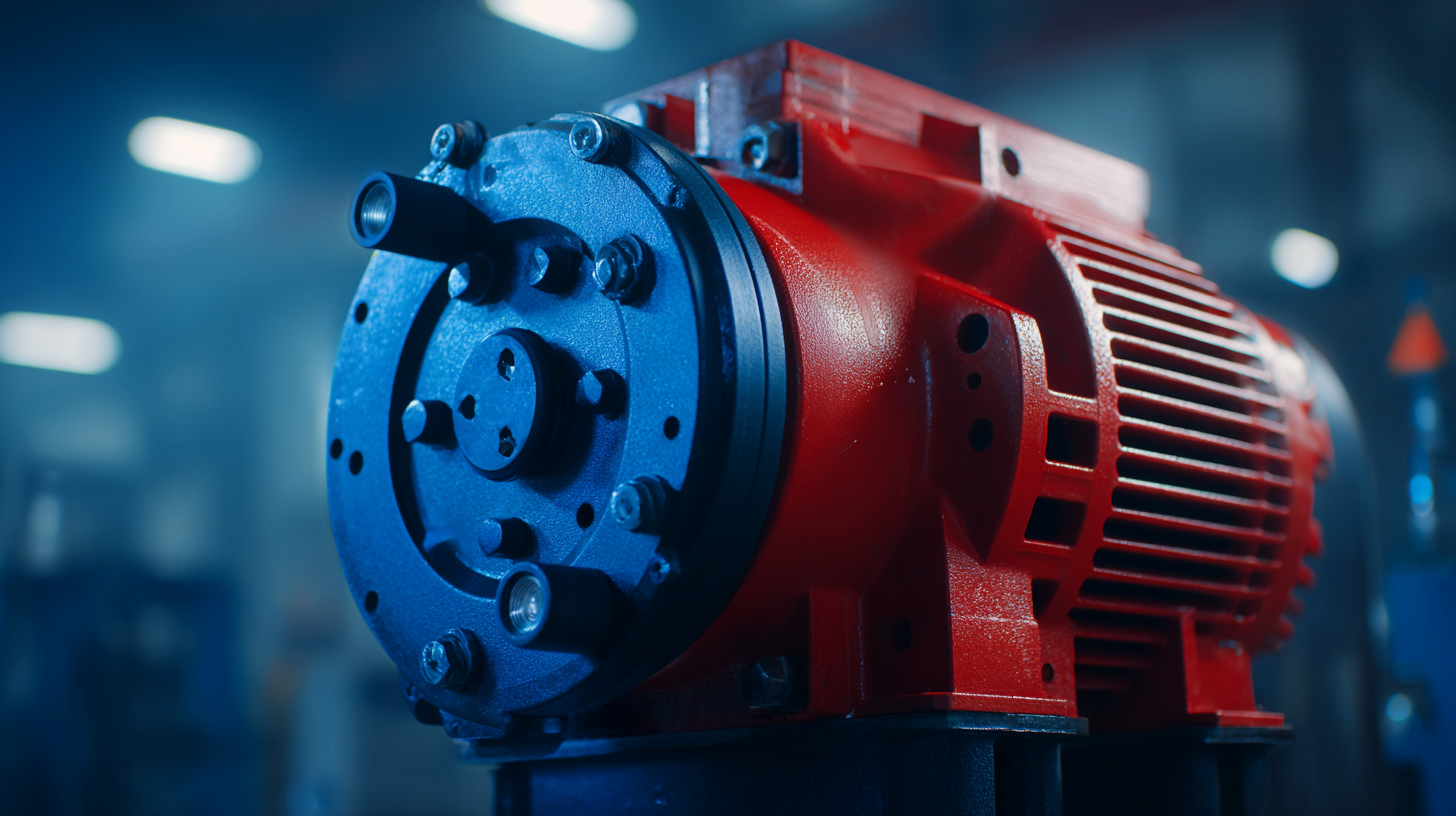

Unleashing the Power of Chinese Manufacturing in Best Air Compressor Spare Parts

In recent years, the global demand for high-quality air compressor spare parts has witnessed a significant surge, driven by the rapid industrialization and expansion of manufacturing sectors, particularly in Asia. According to a report by Market Research Future, the air compressor market is projected to reach USD 39 billion by 2027, with a substantial portion attributed to the pivotal role of spare parts in maintaining operational efficiency. China's manufacturing prowess positions it as a leading supplier in this arena, offering an extensive range of air compressor spare parts that meet international standards for quality and performance.

As businesses increasingly seek reliable and cost-effective solutions, understanding how to harness the advantages of Chinese manufacturing can unlock substantial benefits in terms of efficiency, affordability, and sustainability in the management of air compressor systems.

Exploring the Evolution of Chinese Manufacturing in Air Compressor Spare Parts

The evolution of Chinese manufacturing in the air compressor spare parts industry has been significant, with the market projected to witness substantial growth from 2025 to 2030. As per industry reports, the Chinese air compressor market is expected to expand, driven by innovations in manufacturing technology and increasing demand across various sectors including manufacturing, oil and gas, and renewable energy. The overall industry is classified into categories based on operational modes—rotary, centrifugal, and reciprocating—and product types such as stationary and portable compressors. The lubrication segment further differentiates between oil-lubricated and oil-free compressors, catering to diverse application needs.

The evolution of Chinese manufacturing in the air compressor spare parts industry has been significant, with the market projected to witness substantial growth from 2025 to 2030. As per industry reports, the Chinese air compressor market is expected to expand, driven by innovations in manufacturing technology and increasing demand across various sectors including manufacturing, oil and gas, and renewable energy. The overall industry is classified into categories based on operational modes—rotary, centrifugal, and reciprocating—and product types such as stationary and portable compressors. The lubrication segment further differentiates between oil-lubricated and oil-free compressors, catering to diverse application needs.

Leading up to this growth, major players in the industry are adopting advanced technological solutions to optimize manufacturing processes and improve efficiency. Companies are now focusing on sustainable market segments, positioning themselves strategically to capitalize on the rise of high-growth sectors like

Leading up to this growth, major players in the industry are adopting advanced technological solutions to optimize manufacturing processes and improve efficiency. Companies are now focusing on sustainable market segments, positioning themselves strategically to capitalize on the rise of high-growth sectors like

- Life Sciences

- Food and Beverage

- Clean Energy

As the landscape continues to evolve, the integration of innovative technologies will play a crucial role in enhancing product offerings and driving competitive advantages in the air compressor spare parts market. The collective impact of these factors signifies a transformative phase for Chinese manufacturing, offering a glimpse into the future of the industry.

Key Benefits of Sourcing Air Compressor Spare Parts from China

Sourcing air compressor spare parts from China offers numerous advantages that can significantly benefit businesses in various sectors. One of the primary benefits is the cost-effectiveness associated with Chinese manufacturing. Due to lower labor costs and the availability of a robust supply chain, companies can acquire high-quality components at a fraction of the price compared to other manufacturing hubs. This translates to substantial savings that can be redirected into other critical areas of the business, enhancing overall profitability.

Additionally, Chinese manufacturers are known for their capacity to produce a wide range of components with impressive speed and flexibility. This responsiveness allows businesses to maintain inventory levels that are both efficient and aligned with demand fluctuations. Furthermore, many Chinese manufacturers are increasingly adopting modern technologies such as automation and quality control systems, ensuring that the spare parts are of high quality and reliability. By sourcing from China, companies can not only meet their immediate needs but also foster stronger relationships with suppliers who can support long-term growth and innovation in their operations.

Unleashing the Power of Chinese Manufacturing in Best Air Compressor Spare Parts

This chart represents the efficiency and cost-effectiveness of sourcing air compressor spare parts from China compared to other countries. The data highlights the production volume, average lead time, and cost per unit for air compressor spare parts in various manufacturing regions.

Top Innovations in Chinese Air Compressor Spare Parts Manufacturing

Chinese manufacturing is at the forefront of innovation in air compressor spare parts, as evidenced by significant advancements that enhance efficiency and performance. The projected growth of the global air compressor market from $18.96 billion in 2025 to $29.31 billion by 2032 highlights the increasing demand for high-quality spare parts. Chinese manufacturers are leveraging cutting-edge technologies, such as Artificial Intelligence and IoT, to streamline production processes and improve the durability of their products. This focus on innovation not only supports local industries but also positions China as a leading hub in the global manufacturing landscape.

One notable player in this arena is the recent recipient of a prestigious global leadership award, recognizing exceptional contributions to the industrial air compressor sector. Companies like this are developing a diverse portfolio of spare parts that cater to various industrial applications, ensuring compatibility and longevity. As the Asia Pacific market continues to grow, with forecasts indicating China will maintain a significant share, the emphasis on smart manufacturing and sustainable practices will likely shape the future of air compressor spare parts. The integration of advanced technologies and a commitment to quality is what truly unleashes the potential of Chinese manufacturing in this vital segment.

Digital Transformation: How Technology Powers Chinese Manufacturing

The rapid digital transformation of Chinese manufacturing has revolutionized the production of air compressor spare parts, harnessing advanced technologies to improve efficiency and quality. With automation and robotics integrated into the manufacturing processes, Chinese factories can now deliver precision-engineered components at faster rates than ever before. This shift not only reduces operational costs but also enhances the overall reliability of spare parts, meeting the rising demands of global markets.

Moreover, the use of data analytics and IoT (Internet of Things) has allowed manufacturers to optimize their supply chains and predict maintenance needs more accurately. By collecting real-time data, manufacturers can identify potential issues before they escalate, ensuring a seamless production flow. This technological empowerment enables Chinese manufacturers to respond dynamically to market fluctuations, making them formidable players in the air compressor spare parts industry. The blend of traditional manufacturing prowess with cutting-edge technology truly showcases the potential of Chinese manufacturing on the global stage.

Unleashing the Power of Chinese Manufacturing in Best Air Compressor Spare Parts

| Spare Part Type | Material | Technology Used | Production Capacity (Units/Month) | Export Rate (%) |

|---|---|---|---|---|

| Air Filter | Synthetic Fiber | Automated Filtration Technology | 50,000 | 30 |

| Compressor Valve | Aluminum Alloy | CNC Machining | 25,000 | 45 |

| Lubrication Kit | Specialized Oil | Smart Dispensing | 15,000 | 20 |

| Pressure Switch | Plastic Composite | Microcontroller Integration | 30,000 | 50 |

| Belt Drive | Rubber Compound | Advanced Molding | 40,000 | 25 |

Quality Assurance Practices in Chinese Air Compressor Spare Parts Production

In recent years, the Chinese manufacturing sector has taken significant strides in the production of air compressor spare parts, largely driven by advancements in quality assurance practices. According to a report by the China National Machinery Industry Corporation, over 70% of manufacturers now employ stringent quality control measures throughout the production cycle. This shift not only enhances the durability and performance of spare parts but also aligns with international standards, allowing Chinese manufacturers to compete on a global scale.

Moreover, the implementation of ISO 9001 certification across many production facilities has contributed to a notable reduction in defect rates, sometimes reported as low as 3% in some plants. This level of quality assurance is crucial, given that air compressors are integral to various industries, from manufacturing to HVAC systems. Furthermore, data from the International Compressors Manufacturers Association indicates that over 40% of companies are actively investing in research and development to innovate and improve spare parts quality. The combination of advanced manufacturing techniques and rigorous testing ensures that Chinese air compressor spare parts not only meet but often exceed customer expectations.