Global Excellence in Manufacturing: The Pride of China’s Best Screw Air Compressors

In recent years, the global demand for efficient and reliable screw air compressors has surged, making them a cornerstone of various industrial applications. According to the latest industry report by Market Research Future, the global screw air compressor market is projected to reach USD 34.2 billion by 2025, growing at a CAGR of 4.5% from 2019 to 2025. This remarkable growth underscores the essential role of quality manufacturers in providing advanced technologies and solutions that meet the evolving needs of modern industry. As China emerges as a leader in this sector, understanding how to select a high-quality screw air compressor manufacturer becomes imperative for businesses aiming to enhance operational efficiency and sustainability.

In this blog, we will explore key factors to consider when choosing the best screw air compressors, ensuring that both performance and reliability are paramount in your selection process.

The Evolution of Screw Air Compressors in China: A Timeline of Innovation

The evolution of screw air compressors in China has been marked by significant innovation and technological advancement over the past few decades. Originally introduced in the early 1990s, screw air compressors quickly gained popularity due to their efficiency and reliability. According to a report by Futuresource Consulting, the Chinese market for air compressors is expected to grow at a compound annual growth rate (CAGR) of over 5% from 2020 to 2025, highlighting the increasing demand for advanced compressor technology.

In the early 2000s, Chinese manufacturers began investing heavily in research and development, leading to the production of high-quality screw compressors that rivaled their Western counterparts. By 2015, companies like Atlas Copco and Ingersoll Rand faced stiff competition from local brands such as Sullair and Kaishan, which contributed to a dramatic reduction in costs for end-users. Additionally, the integration of IoT technology into screw air compressors has enabled real-time monitoring and predictive maintenance, further enhancing their operational efficiency.

This timeline of innovation illustrates China's commitment to achieving global excellence in manufacturing, solidifying its position as a leader in the air compressor industry.

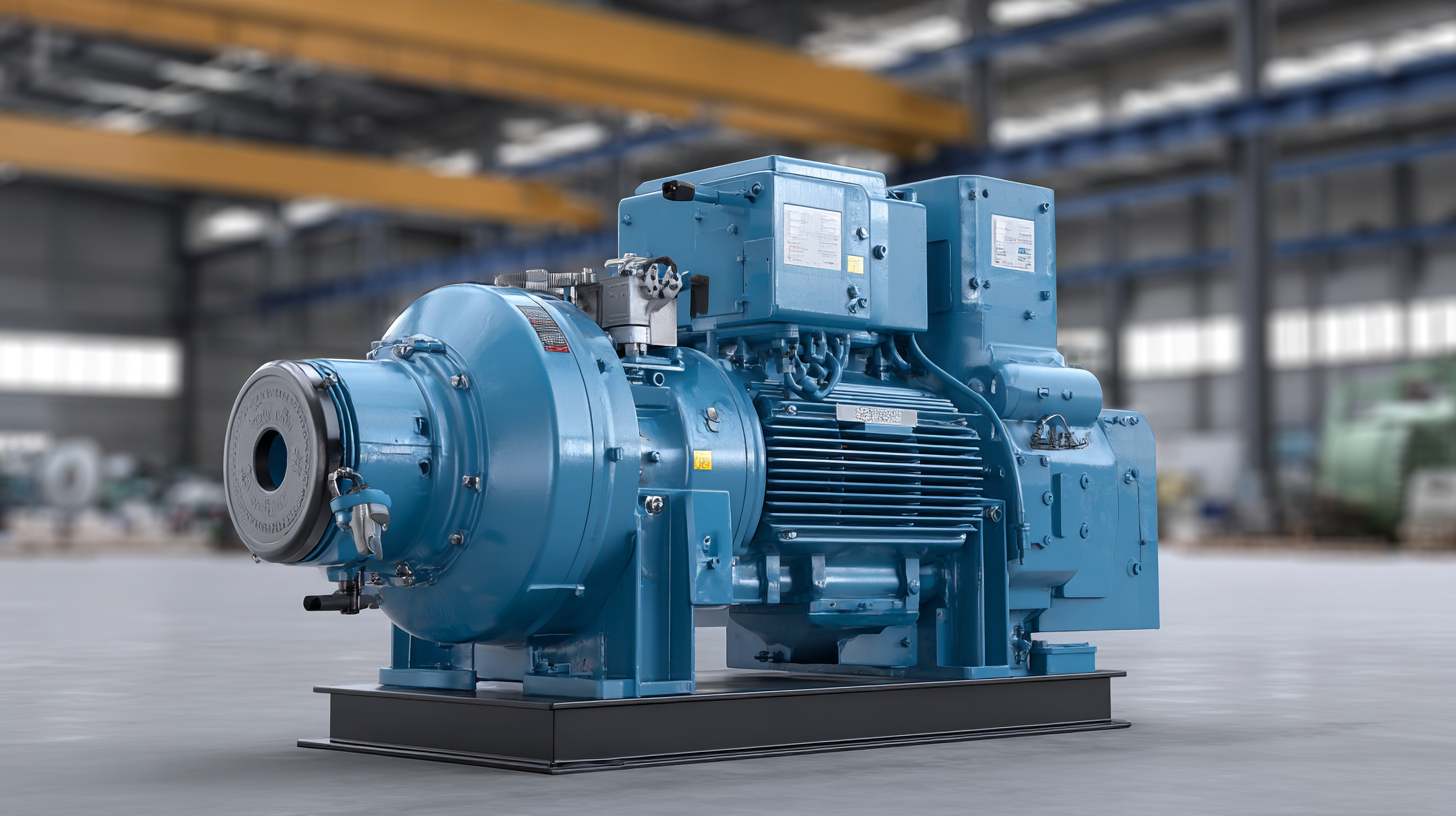

Key Features of China's Leading Screw Air Compressors: What Sets Them Apart

China's leading screw air compressors stand out in the global market due to their innovative technology and impressive performance specifications. According to a report by MarketsandMarkets, the air compressor market is projected to reach $41.76 billion by 2027, with screw air compressors growing at a significant rate due to their efficiency and reliability. Key features that define the best screw air compressors from China include advanced energy-saving technologies, reduced noise levels, and compact designs that optimize space in industrial settings.

Incorporating smart technology in these compressors enhances operational efficiency. For instance, the integration of IoT systems allows for real-time monitoring and predictive maintenance, thereby minimizing downtime. Additionally, many models boast high-efficiency motors that can reduce energy consumption by up to 35%. Such advancements not only enhance sustainability but also contribute to cost savings in the long term.

Tips: When selecting a screw air compressor, consider the specific energy consumption ratings and noise levels according to your operational needs. It’s wise to compare the warranty and service agreements provided by manufacturers, as these can significantly affect the longevity and reliability of the equipment. Investing in a reputable brand with proven data can also lead to better performance and lower total operational costs.

Sustainability and Efficiency: The Environmental Edge of Chinese Screw Air Compressors

As the manufacturing sector increasingly embraces sustainability, Chinese screw air compressors have emerged as a benchmark for efficiency and environmental responsibility. According to a report by MarketsandMarkets, the global air compressor market is projected to reach USD 41 billion by 2025, with a significant portion attributed to the rapid advancements in water-cooled and oil-free screw compressors. These technologies not only minimize energy consumption but also dramatically reduce greenhouse gas emissions, making them ideal for eco-conscious industries.

Moreover, Chinese manufacturers have been at the forefront of integrating innovative energy-saving features into their screw air compressors. For instance, the introduction of Variable Speed Drive (VSD) technology can yield energy savings of up to 35%, as reported by Energy Efficiency Business studies. This not only lowers operating costs for businesses but also significantly cuts carbon footprints. As industries transition towards greener practices, the capabilities of these compressors will play a pivotal role in achieving sustainability goals while maintaining robust performance.

Global Market Trends: China's Position in the Future of Air Compressor Manufacturing

China has emerged as a significant player in the global air compressor manufacturing market, especially in the screw air compressor segment. As the industry is projected to grow to USD 21.34 billion by 2033 at a compound annual growth rate (CAGR) of 5.7%, China's innovative approach and robust production capabilities position it well for future success. The increasing demand for efficient and reliable air compression solutions across various industries underscores the transformative role that Chinese manufacturers play in driving market growth.

Tips for businesses looking to enter the air compressor market include focusing on energy-efficient technologies and understanding local market needs. By investing in innovation and sustainability, manufacturers can cater to the growing demand for oil-free and mobile air compressors, which are expected to trail significant growth rates over the next decade. Tailoring products to meet these needs will not only enhance customer satisfaction but also solidify a brand's position in a competitive marketplace.

Furthermore, staying updated with global trends is essential. The international landscape is shifting towards industrial applications that prioritize automation and efficiency. Companies should leverage advanced manufacturing techniques and collaborate with local stakeholders to optimize their supply chains and make a meaningful impact in the evolving market. Emphasizing these strategies can help businesses harness growth while contributing to the global conversation on air compressor technologies.

Investing in Technology: The Role of R&D in Enhancing Screw Air Compressor Performance

In the competitive landscape of manufacturing, the importance of research and development (R&D) cannot be overstated, especially for industries like screw air compressors. Investing in advanced technologies not only enhances the performance of these compressors but also positions manufacturers as leaders in innovation. By focusing on R&D, manufacturers can explore new materials, improve energy efficiency, and develop intelligent control systems that optimize compressor operations.

Moreover, the role of R&D extends beyond mere product enhancement. It fosters a culture of continuous improvement, allowing manufacturers to respond swiftly to market demands and environmental regulations. As companies invest in sophisticated testing facilities and skilled research teams, they can unlock new capabilities, such as reduced noise levels and extended lifespan of compressors. This commitment to innovation is not just about staying competitive; it's about contributing to a sustainable future in manufacturing and energy consumption. By prioritizing R&D, China's leading screw air compressor manufacturers are setting the stage for remarkable advancements that cater to both domestic and global markets.