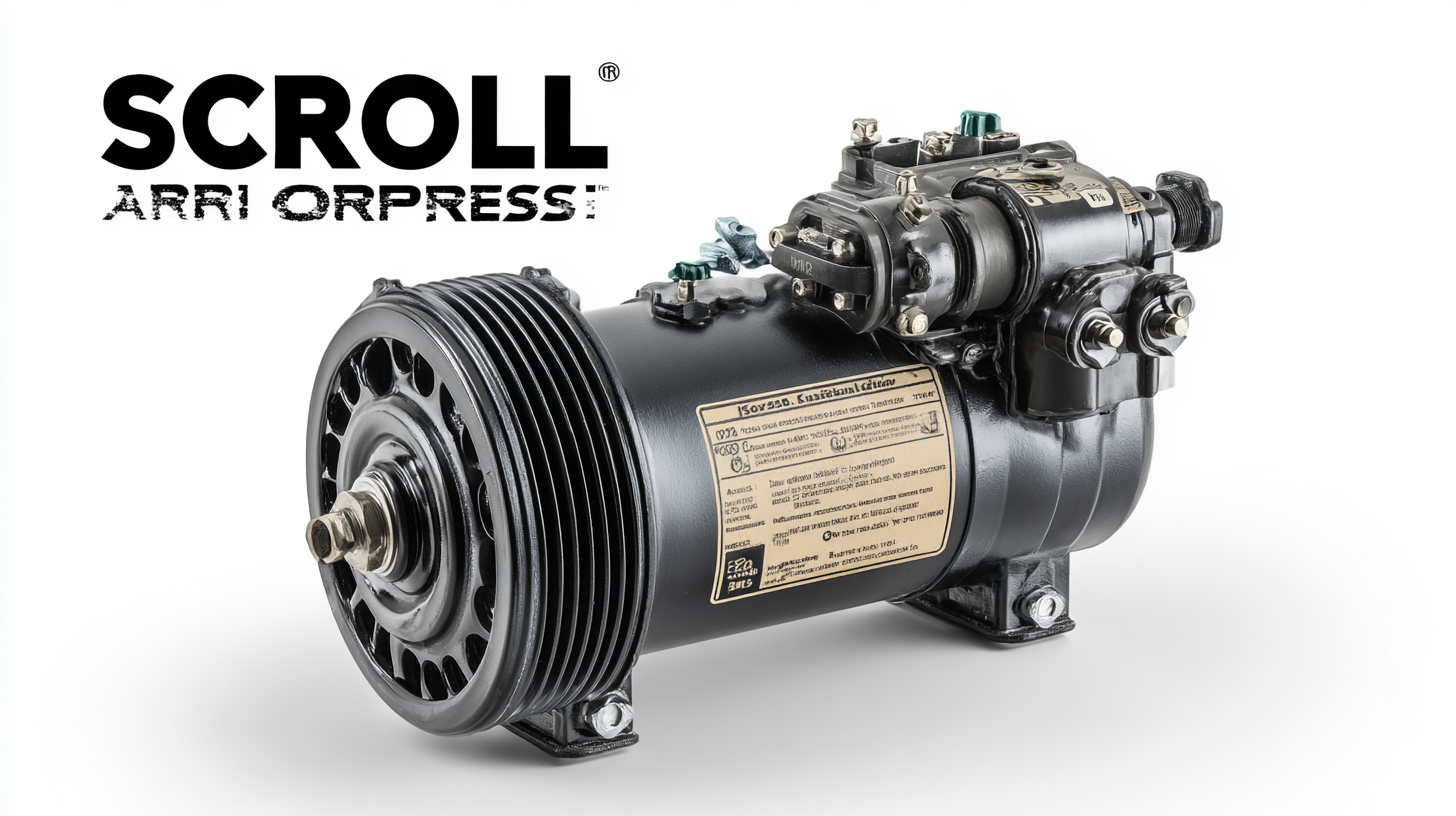

7 Essential Tips for Selecting the Best Scroll Air Compressor for Your Needs

In the ever-evolving landscape of industrial equipment, selecting the right scroll air compressor is paramount for optimizing performance and efficiency. According to a recent market research report by Grand View Research, the global air compressor market is projected to reach $40.6 billion by 2025, with scroll compressors gaining traction due to their energy efficiency and low maintenance requirements.

As businesses strive to enhance productivity while minimizing operational costs, the demand for high-quality scroll air compressors continues to rise. In this context, understanding how to choose the best model to meet your specific needs becomes crucial. This blog will provide essential tips for selecting the most suitable scroll air compressor, ensuring that you invest wisely in a reliable supplier and a product tailored to your operational requirements.

Key Features to Look for in a Scroll Air Compressor for 2025

When selecting a scroll air compressor for your needs in 2025, it's crucial to understand the key features that set the best models apart. First and foremost, the efficiency of the compressor plays a significant role. According to a report by the Compressed Air and Gas Institute (CAGI), modern scroll compressors can achieve energy efficiencies exceeding 80%, which means reduced operating costs and less environmental impact. Look for models that offer variable speed drives, as these can adjust the compressor's output based on the demand, further enhancing efficiency.

Additionally, noise level is another important feature to consider. Scroll compressors are known for their quiet operation, typically generating noise levels around 60 dB, making them ideal for environments where noise is a concern. In sectors like healthcare or hospitality, where compressor operation is continuous, the reduced acoustic footprint becomes a significant advantage.

Lastly, maintenance requirements cannot be overlooked. The trend towards oil-free designs is growing, as shown by the latest market analysis from Freedonia Group, predicting a 5% annual growth in oil-free scroll compressor usage. These models not only require less routine maintenance but also offer cleaner air supply, which is essential for sensitive applications like pharmaceuticals and food processing.

7 Essential Tips for Selecting the Best Scroll Air Compressor for Your Needs - Key Features to Look for in a Scroll Air Compressor for 2025

| Feature | Description | Importance |

|---|---|---|

| Noise Level | Scroll compressors generally operate at lower noise levels compared to traditional piston types. | Essential for quiet environments, such as offices or residential areas. |

| Efficiency | Look for energy-efficient models that consume less power and save on electricity bills. | High efficiency improves overall operating costs; ideal for continuous use. |

| Size and Portability | Consider the compressor size based on your workspace and whether you need a portable solution. | Key for mobile operations and small spaces. |

| Pressure Capacity | Select a compressor that meets your specific pressure requirements for different applications. | Vital for ensuring the compressor can handle your tools and equipment effectively. |

| Maintenance | Choose models that require minimal maintenance and have easy access for servicing. | Saves time and money; ensures longevity of the unit. |

| Heat Management | Look for compressors with effective heat dissipation features. | Prevents overheating, leading to better performance and durability. |

| Warranty and Support | Consider the warranty period and available customer support options. | Provides peace of mind and assistance in case of issues. |

Understanding Energy Efficiency Ratings and Their Impact on Performance

Understanding energy efficiency ratings is crucial when selecting the best scroll air compressor for your needs. These ratings, often represented as Energy Efficiency Ratio (EER) or Coefficient of Performance (COP), provide a quantifiable measure of how effectively an air compressor converts electrical energy into mechanical energy. According to the U.S. Department of Energy, equipment that scores above 10 EER can significantly reduce operational costs and minimize environmental impact. Therefore, when considering a compressor, look for those that not only meet but exceed standard efficiency ratings.

When selecting a scroll air compressor, prioritize models that boast high energy efficiency ratings to ensure optimal performance and longevity. This is particularly important in demanding applications where energy costs can accumulate rapidly. Additionally, consider units equipped with variable speed drives (VSD), as these allow for greater control over energy usage while maintaining performance levels. Studies indicate that compressors with VSD can save up to 30% in energy consumption compared to fixed-speed models.

Moreover, regularly maintaining your compressor can further enhance its energy efficiency. Simple actions such as cleaning filters and checking for leaks can lead to substantial efficiency gains. In fact, the Compressed Air and Gas Institute states that up to 30% of energy used in compressed air systems is wasted due to improper maintenance. By making informed decisions based on energy efficiency ratings and implementing regular maintenance protocols, you can secure the best scroll air compressor for your operational needs while maximizing performance and reducing costs.

Energy Efficiency Ratings of Scroll Air Compressors

This chart displays the Energy Efficiency Ratings (measured in kW per kg per hour) of various scroll air compressor models. Higher ratings indicate better efficiency, which can significantly impact overall operational costs and performance.

Exploring Alternative Air Compression Technologies for Different Needs

When selecting an air compressor, it's crucial to explore alternative compression technologies that suit specific applications.

Scroll air compressors have gained popularity due to their efficiency and low noise levels, making them ideal for environments where sound pollution is a concern.

However, depending on your application's demands, you might consider options like rotary screw compressors, piston compressors, or even diaphragm compressors, each offering unique advantages.

Scroll air compressors have gained popularity due to their efficiency and low noise levels, making them ideal for environments where sound pollution is a concern.

However, depending on your application's demands, you might consider options like rotary screw compressors, piston compressors, or even diaphragm compressors, each offering unique advantages.

One essential tip is to assess your air demand thoroughly. For continuous operations, a rotary screw compressor might be more efficient, whereas for intermittent use, a scroll compressor could suffice. Additionally, consider the required pressure levels and flow rates; some compressors are better suited for high-pressure tasks, while others excel in providing stable, lower pressure output.

Another important factor is maintenance. Scroll compressors typically require less maintenance compared to their piston counterparts, which can be advantageous for businesses looking to minimize downtime. Always review the longevity and service interval of the technology you choose, ensuring it aligns with your operational needs and maintenance capabilities. Exploring these alternatives can help you choose the right air compressor that not only meets your needs but also enhances the efficiency of your operations.

Future Trends in Scroll Air Compressor Design and Functionality

As the demand for energy-efficient and quiet operation continues to rise, the future of scroll air compressor design is evolving significantly. Manufacturers are focusing on incorporating advanced technologies such as variable speed drives, which optimize energy consumption based on the actual workload. This innovation not only enhances performance but also reduces operating costs, making scroll compressors an increasingly attractive option for various industrial applications.

Another trend gaining traction is the integration of smart technology into scroll air compressors. With IoT capabilities, these compressors can now monitor operational parameters in real-time, enabling predictive maintenance and minimizing downtime. Users can access data remotely, which allows for better management of air compressor systems and immediate response to any operational issues. As industries push for automation and efficiency, scroll air compressors equipped with these cutting-edge features are positioned to make a significant impact on productivity and reliability.

Evaluating Cost vs. Benefit: Choosing the Right Model for Your Budget

When considering the purchase of a scroll air compressor, evaluating cost versus benefit is crucial. A recent industry report indicates that scroll compressors offer up to 30% greater energy efficiency compared to traditional piston models. This efficiency translates into lower operating costs over time, making them a worthwhile investment for businesses focused on long-term savings. By analyzing your specific needs and the expected operational savings, you can make a more informed decision.

One essential tip is to assess your usage requirements carefully. If your applications demand continuous operation, a higher-quality scroll compressor may be more beneficial, despite a potentially higher upfront cost. Additionally, consider the maintenance costs; scroll compressors typically require less frequent servicing due to fewer moving parts. Another important factor is the noise level, as many scroll compressors operate at significantly lower decibel levels than their counterparts, which can enhance the working environment.

Lastly, don't overlook warranty and customer support when evaluating different models. A compressor with a robust warranty and reliable support can reduce the total cost of ownership significantly. Researching manufacturers’ reputations and user reviews can provide insights into their reliability and overall value, helping you select a model that aligns with both your budget and performance needs.